LOGO system

Efficient conveying technology guarantees competitive advantages

High-performance mixing and conveying technology is an important productivity factor at construction sites – and not just for major projects. More and more professional painters are using machine technology even on small construction sites. To cover this need, Brillux has developed intelligent conveying technology systems in close cooperation with professional painters: the Brillux LOGO systems. Their targeted use brings maximum flexibility with optimal efficiency. This means: no time-consuming preparation of the construction materials by hand, no lugging buckets, and no expensive set-up times.

C 250 and C 500: More productivity on large construction sites

These two strong container systems for emulsion paints and other liquid products put an end to unprofitable material storage times. Brillux LOGO C makes coating walls and facades easy: simply tap the container, start work, and create a surface. The Brillux delivery service brings the completely filled LOGO-C containers exactly where they are needed – flexibly, on-time, reliably.

The advantages:

- Capacity: 250 or 500 liters

- 2-inch DIN-C connection for airless devices

- Can be equipped with two work ports

- Low residual quantities via practical conservation trough in the container

- Piston pump for a conveying distance of up to 150 m

- Lockable tap and cover

- Complete product range of application tools and accessories available directly from Brillux

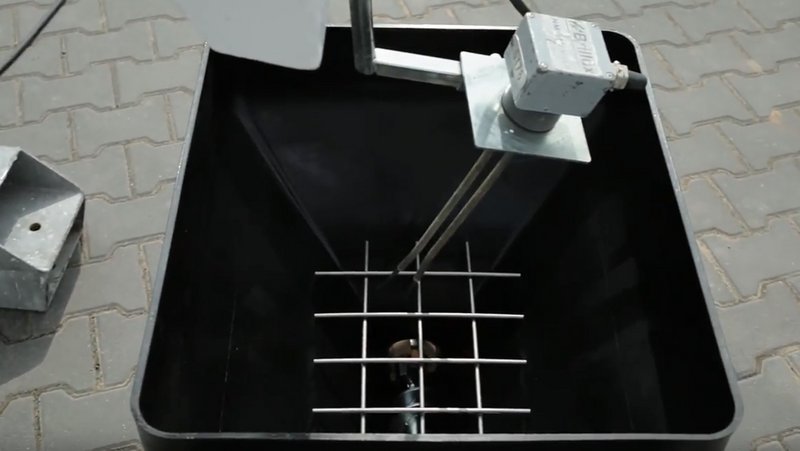

S 1600 and S 5: well-conceived down to the smallest detail

For measurably higher productivity at the construction site: LOGO S 1600 and LOGO S 5 combine maximum filling capacity with state-of-the-art mixing and conveying technology. Both systems are extremely low-maintenance. You only have to set the consistency of the conveyed material once at the start of work – then the intelligent LOGO control electronics automatically ensure completely consistent material quality. Conveying technology systems combined with the highly developed Brillux logistics therefore make working on large construction sites even more efficient.

The advantages:

- Capacity: 1,600 or 4,800 kg

- Electronic control system for completely uniform material consistency and smooth interaction of the continuous flow mixer and conveyor

- Early warning system with automatic switch-off: water pressure monitor provides maximum operational safety

- Depending on the material, conveyor and hose: conveying capacity of up to 50 m

- Smooth communication via wet probe technology with worm conveyors

- Variable telescopic stand for adjusting to the ground

- "Just-in-time" filling in minutes with the Brillux Big Bag

- Complete product range of application tools and accessories available directly from Brillux

P 1000: A clean solution

With a filling capacity of up to 1,000 kg, LOGO P 1000 is perfect for use on medium-sized construction sites. The Brillux construction site service delivers the LOGO silo to the desired construction site "just-in-time": set it up, connect it to the conveyor, and it is ready to use. Extremely practical: as is the case for LOGO P 2000, LOGO P 1000 also results in a clean construction site.

At the end of the working day, simply seal the hose airtight or place the spray lance in water overnight. On the next working day, users can immediately pick up where they left off without long setup times.

The advantages:

- Filling capacity: up to 1,000 kg

- High conveying distances of up to 60 m, depending on the worm conveyor

- Funnel-shaped silo made from double-rolled stainless steel for optimal flow

- Height-adjustable feet for variable connection of worm conveyors and easy material removal

- Complete product range of application tools and accessories available directly from Brillux

P 2000: For medium to large building projects

The LOGO P 2000 conveyor system is a closed system. It stands for minimal setup and application times and maximum productivity. Up to 2,000 kg paste-like and cement-free, ready-to-use material can be stored and applied efficiently. Typical Brillux: intelligent detail solutions like the variable pump output for exact control of the flow rate or the finely adjustable liquid pump metering. Both guarantee consistently optimal work results – in all weather conditions.

The advantages:

- Filling up to 2,000 kg – with refill silo up to 3,000 kg

- Stainless steel silo with 1x height adjustable feet and integrated conveyor

- No daily cleaning required

- Exact metering of the quantity being conveyed via presettable pump output

- Large conveying distance of up to 60 m

- Funnel-shaped silo made from double-rolled stainless steel for optimal flow