In the spotlight: In just one work step, light filler materials can be used to create significantly thicker film thicknesses, often double as thick as conventional filler materials.

A key side effect: The lower material weight means that the user does not need as much strength to apply the light filler material. In addition, they are also much easier to sand – as shown by tests both in the laboratory and in practice: Light filler materials allow up to 30 percent more material to be applied in the same time and are also more efficiently sanded.

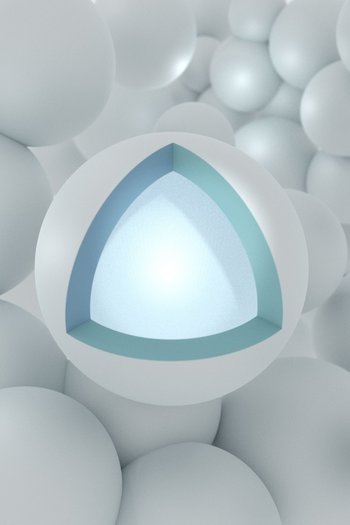

In contrast to conventional filler materials, the structure of which is made from massive solid spheres, light filler materials use hollow spheres. These can be broken up more easily and therefore make it easier to sand them down.

Brillux light fillers don’t just save your strength, but also your time! The light filler materials have a range of other advantages:

- Easier to handle in the workshop and on the construction site, thanks to their lighter weight

- Greater quantities can be loaded, especially in small vehicles

- Require significantly less effort to apply

- Higher film thicknesses – often double the thickness – can be achieved

- Efficiently sanding, as up to 30% more material can be removed in the same time

- Create spotlessly smooth walls

- The right light filler material for any substrate – inside or outside

- Even more efficient to apply in combination with Fiberglass Filling Nonwoven 1560