Concrete protection and renovation Repair and protection

Concrete is and remains an indispensable building material in state-of-the-art building construction and civil engineering. Reinforced concrete in particular is classed as the building material of the future. But its service life is not unlimited. Buildings and components made from reinforced concrete must therefore be checked regularly for damage. The sooner faults are identified, the easier it is to eliminate them. Brillux provides an extensive range of products for professional protection and repair of concrete components. All products meet the requirements of the Guidelines on Concrete Repair of the German Committee for Reinforced Concrete (DAfStB) and ZTV-ING ("Additional technical terms of contract and guidelines for civil engineering works") from the Federal Ministry of Transport and Digital Infrastructure.

Repair

For high requirements on appearance and function

Easy handling with a wide range of uses: The special mortar Reprofill K 765 and Fine Filler 804 already cover 90 percent of the application cases in the field of concrete repair.

Fractured corners and edges

Reprofill K 765 is ideally suited for everyday problem cases such as fractured corners and edges, and for smoothing substrates, e.g., for mounting a thermal insulation composite system. Fast mixing in just two minutes, high wet adhesive strength, and good stability for modeling corners or similar structures set standards with regard to versatility.

Large-surface filling

For large-surface filling and for leveling already repaired substrates, it is advisable to use the PCC Fine Filler 804. In addition to the traditional manual application, it is also suited for use in wet-spray application. For this, the material is available in the 750 kg big bag in addition to the 25 kg sack. The build-up with Brillux PCC Basis Protection 801, PCC Filling Mortar 805 and PCC Fine Filler 804 has been tested in accordance with the repair directive and ZTV-ING. The products meet the requirements of EN 1504-3 or EN 1504-7 and are subject to continuous monitoring.

Protection measures

Professional protection from carbonization

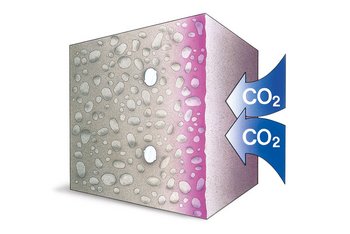

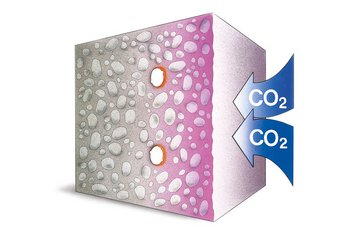

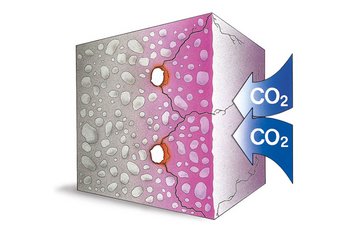

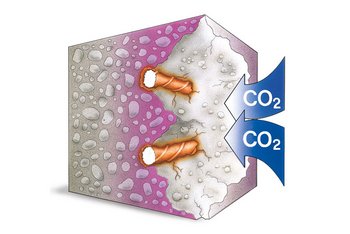

Surface protection systems generally reduce water and carbon dioxide absorption. The progressing carbonization of the concrete is largely prevented in this manner. This eliminates the only, real weakness of reinforced concrete – the corrosion of the reinforcement and resulting flaking of concrete components.

Advantages of the surface protection systems

- Protection from water and contaminants, such as CO2, combined with high water vapor diffusion

- Increased wear resistance

- Color design option

- Reduced soiling and infestation with microorganisms

Different coating build-ups

The described coating build-ups are systems that have been tested in accordance with the Guidelines on Concrete Repair of the German Committee for Reinforced Concrete (DAfStB) and ZTV-ING ("Additional technical terms of contract and guidelines for civil engineering structures") These products conform to the requirements of EN 1504-2 and are subject to constant monitoring.

The coating is in accordance with OS 2 (OS B) is a preventative protection for fully exposed concrete parts with adequate water drainage. The film-forming coating reduces the absorption of water and the substances dissolved in the water. The result: The significant reduction in the CO2 absorption virtually stops the carbonization in the concrete. The steel reinforcement remains permanently protected. The standard build-up: Hydrophobing and at least two top coats with a polymer dispersion. Also possible:

- Individual color design using the Brillux Color System

- Factory provision of Protect quality – with film protection against algal and fungal infestation

OS 4 (OS C) is the standard measure after reprofiling due to reinforced concrete corrosion. Requirement: crack-free, vertical concrete substrates The standard build-up: A full-surface leveling filling with PCC fine filler and at least two top coats with a polymer dispersion. Also possible:

- Individual color design using the Brillux Color System

- Factory provision of Protect quality

OS 5a is a measure performed to treat concrete cracks close to the surface. In contrast to OS 4, the surface protection layer is significantly thicker and more elastic. The standard build-up: A full-surface, leveling filling with PCC fine filler and two top coats with a UV-networking polymer dispersion. Also possible:

- Individual color design using the Brillux Color System

- Factory provision of Protect quality